Morgan are a global materials business who apply world-class materials science and manufacturing expertise to solve technical challenges that customers face every day.

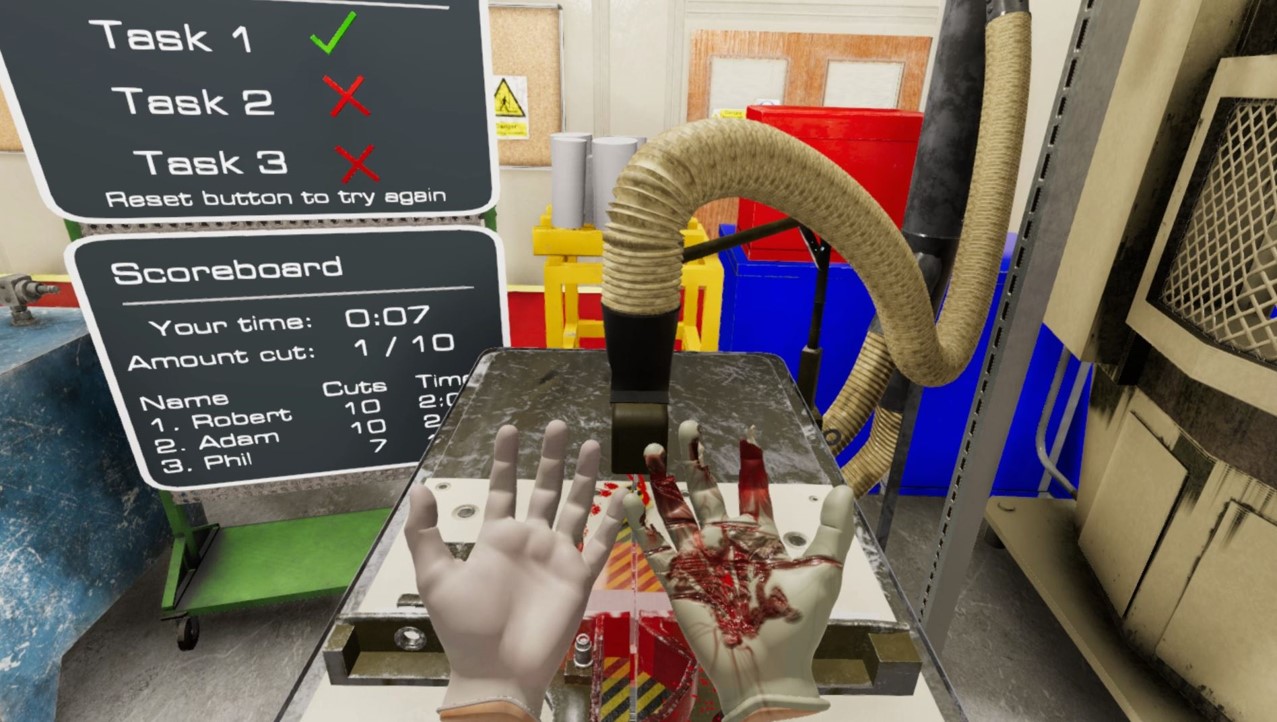

As part of their manufacturing process a range of complex equipment including circular saws and lathes are used by their staff. One of the main causes of injury in the workplace is complacency. Luminous and Morgan came up with an experience that not only reinforced best practice but also highlights starkly the consequences when things go wrong.

To build an accurate 3D environment the Luminous team 3D laser scanned a real factory and modelled it in the Unity Games engine using the 3D point cloud as a reference.

To make the experience as realistic as possible a Leap Motion sensor was combined with an HTC Vive headset for the user interactions. Leap motion is uan external depth sensing device that allows a users real hands to be tracked in VR. With precise hand tracking users can see and interact with a range of objects naturally with out the need for external controllers.

Morgan are currently deploying the solution into their ‘safe work corners’ across there UK factory’s with plans to build on the system in the future with more machines and scenarios in development.