Optimize your processes with Interactive Digital Twins

Enhance remote monitoring, training, and productivity with real time digital twins.

Enhance remote monitoring, training, and productivity with real time digital twins.

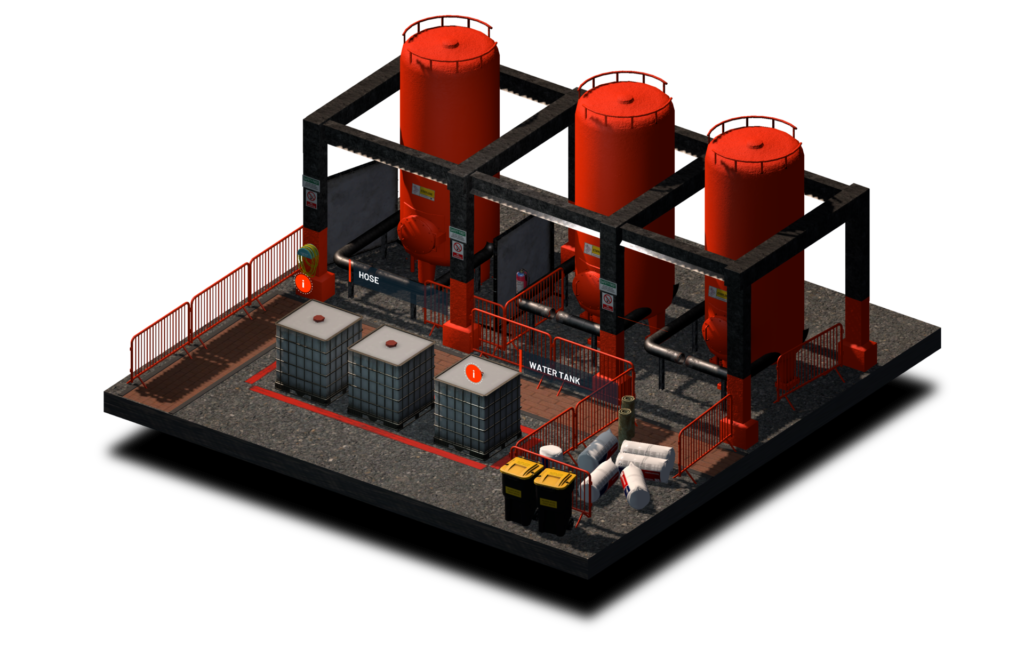

A digital twin is a virtual, digital representation of a physical place, building or asset. The concept of a digital twin has been around for some time, however advances in 3D Laser Scanning, real-time 3D technologies and IoT sensors are allowing companies to harness them to transform operational processes, providing improved efficiency and informed decision making.

60% of organizations consider digital twins a key strategic element of their digital transformation.

This is the first stage in the development of a digital twin and is a 3D representation of a real-world asset or location.

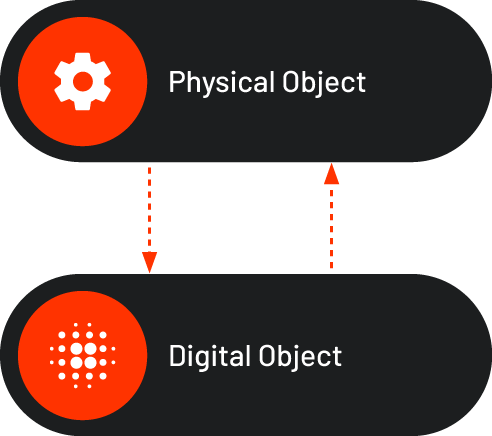

Users may enter or extract information from the digital model, but this is a manual, not yet automatic process. A digital model can still be used for many applications from simulating processes, virtual training & design planning.

![]()

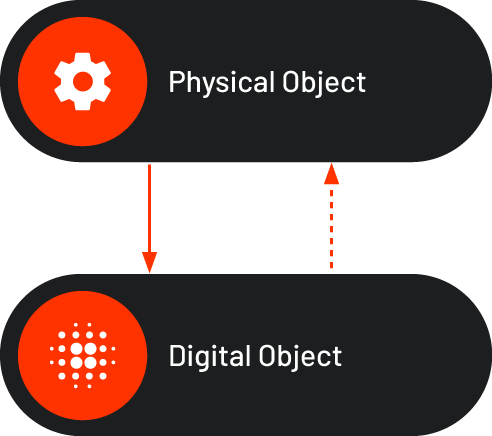

A digital shadow takes the digital model and brings it to life with real time data from equipment or IoT sensors in the facility. Using pointcloud data from Ivion, the Unity Games engine, and the Luminous XR platform we can take a real time 3D model of the facility and connect it to sensor data which gives operators a virtual, collaborative view of operations.

Now you and your colleagues can jump into virtual reality version, view the data together and discuss as if you were on site from anywhere in the world.

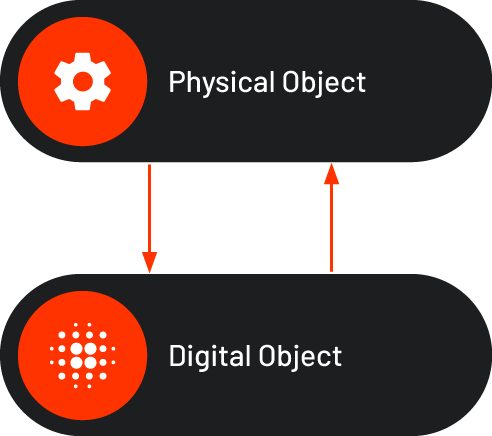

A ‘true’ digital twin requires a 2-way, real-time flow of data between the virtual and real-world environments.

In this instance, an operation in the digital twin would update instantly in the real world, and a real-world process would automatically be updated and shown in the digital twin. The two are completely synchronized, meaning organizations can benefit from making informed and timely decisions to improve operations.

There are many benefits of a digital twin, these include:

Digital Twins connected to the Luminous Platform allow multiuser collaborative meetings or training. Using PORTAL you can schedule virtual meet-ups, training sessions to walk the line and familiarise staff with equipment and processes or virtual tours.

Luminous have experience working with a range of IoT sensors or older systems such as SCADA & Modbus to capture process equipment and sensor data into the digital shadow and digital twin.