Preparing for the next industrial revolution

The manufacturing sector is changing. New technologies, Industry 4.0, the drive for digitalisation, and the benefits it brings are fuelling a new industrial revolution.

Nearly all manufacturing industries are suffering from skills gaps and a shortage of employees, with experienced staff retiring and a loss of vital knowledge and experience.

Extended Reality (XR)

The solution? This can be mitigated by using new immersive training technologies that encapsulate the training experience of these key skills.

XR training spans a variety of devices. On one side, you have augmented reality and devices like smartphones or glasses that allow a visual overlay of enhanced information on a screen, while seeing the world around you. Virtual Reality where wearing VR glasses you are in a closed-off, simulated digital environment.

Between these, there is also a new category of mixed reality. This enables you to see the real world but using either holograms or passthrough video cameras allows 3D content to be augmented seamlessly into your surroundings.

The Luminous XR platform allows you to harness these devices to enhance training, operations and maintenance procedures. XR training results in a huge ROI as well as increased engagement, confidence and accelerated proficiency for new staff.

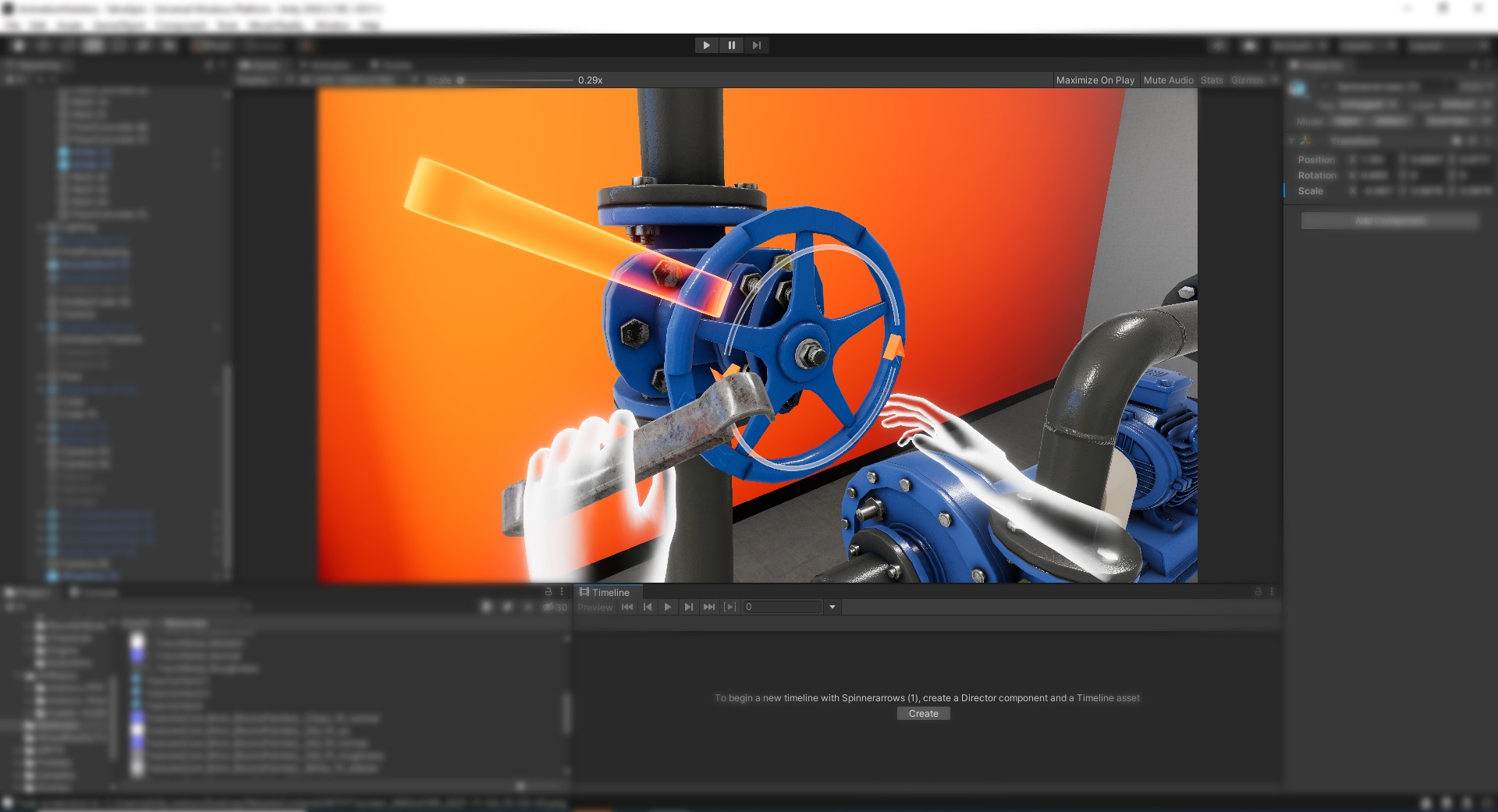

Learning By Doing with VR Immersive Training

VR learners are 275% more confident to apply their skills learned after training and can be trained up to 4x faster than traditional learning methods.

In a manufacturing environment, most new members of staff will learn specific operational procedures by shadowing an experienced operator, this is slow and restrictive.

One way around this is to build a virtual digital twin of your factory and the different lines and equipment within it, and train staff virtually.

Luminous have a background in 3D laser scanning and have the ability to quickly and efficiently digitise your plant to create an accurate real-time 3D digital twin.

Once we have the 3D models, standard operating procedures can be replicated. The Luminous platform then supports multiuser training where students can meet up in the virtual version of your facility and be taken through the required training.

This reduces the need for inductions and permits to work, which can be time-consuming and allows them to train in a safe, repeatable environment.

The results of this are that when the trainee does go to the site for the first time, they are already familiar with it and the different types of equipment and operating procedures.

Customer using interactive digital twins to virtually train staff are seeing a 50% reduction in on-the-job training times and are also able to drastically increase the number of students being trained at a single time.

Mixed Reality for training, fault finding and support

Mixed Reality using devices like the Microsoft HoloLens 2 allows holographic instructions to be overlaid on real equipment in a live operating environment. In a manufacturing setting there a several applications for Mixed Reality, including:

Learn As You Go

Using a HoloLens headset, 3D holographic instructions can be overlaid on the real equipment guiding the user through complex processes. This can be supplement by additional content such as how-to videos or technical documentation. By using mixed reality, these can be pinned around the operator in the real environment providing access to multiple real-time sources of data and virtual screens.

Save Costs through Remote Assistance

Using the HoloLens2 an operator can dial in a remote expert to see what they are doing and guide them through the process. This means instead of flying in an expert and slowing production, a member of staff with minimal experience can be guided through a process of fault finding and repairing complex equipment through VR skill training, with the expert seeing everything and providing access to interactive documentation.

Work with Contextual Data in Real-time

Another application is the ability to access contextual data from IoT devices or live plant equipment and machinery. This allows a factory operator instant access to critical information such as operation speed & performance and temperature & environmental data all through a heads-up display, allowing them to make better informed operational decisions.

Level up Learning with Luminous

Data Analytics & Reporting

Multi Language Support

Trainer & Trainee Dashboards

Multiuser Mode

Desktop Interactions Mode

Luminous XR Platform

The Luminous XR Platform is an end-to-end solution for authoring, managing and deploying Immersive multiuser VR training for hundreds to thousands of students.

Our unique solution provides a visual scripting tool (FLOW) that enables fast, efficient creation of performance-based, feature-rich VR training content. This content is then managed and delivered via our VR Platform (PORTAL) and our single launcher application.

FEATURES:

- Creating VR training content

- Managing users & classes

- Assessing students progress

- Capturing training analytics & producing reports

- Scheduling and monitoring multiuser VR training

- Delivering assigned content via VR/Desktop

- Managing content across multiple devices